With the help of welding equipment, reliable connections of metal structures are created, water supply lines are installed, and repair work is performed. The data below will help you choose a quality inverter. Manufacturers offer a wide range of products in the respective equipment segment. For an accurate comparative analysis, it is necessary to take into account significant consumer parameters, to clarify the opinion of users. It will not be difficult to make the right decision if you study the TOP of the best models of welding inverters. Expert assessments are supplemented with comments based on real operating experience.

- How to choose a welding inverter

- The best inexpensive welding inverters

- 1. ELITECH IS 200H (TIG, MMA)

- 2. RESANTA SAI-190 (MMA)

- 3. Svarog REAL ARC 200 (Z238N) (MMA)

- 4. Fubag IR 200 (MMA)

- The best welding inverters for quality and reliability

- 1. Wester MIG 140i (MIG / MAG, MMA)

- 2. Svarog REAL ARC 220 (Z243N) (MMA)

- 3. RESANTA SAIPA-200C (MIG / MAG)

- 4. Quattro Elementi MultiPro 2100 (TIG, MIG / MAG, MMA)

- The best universal welding inverters

- 1. Fubag IRMIG 180 SYN (TIG, MIG / MAG, MMA)

- 2. Solaris MULTIMIG-227 (MIG / MMA / TIG) (TIG, MIG / MAG, MMA)

- 3. Aurora SPEEDWAY 180 (TIG, MIG / MAG, MMA)

- Which welding inverter is better to buy

How to choose a welding inverter

To find an inexpensive but good device, you need to clarify the area of application. For the rare performance of individual operations lasting 15-20 minutes, a high-quality household model is quite suitable. If long operating cycles are expected (up to 8 hours or more), purchase professional-level welding inverters.

Other criteria:

- by welding current determine the main functionality;

- universal inverters support several modes (manual MMA, TIG and semi-automatic MIG-MAG);

- ON duration shows the permissible welding duration in one working cycle (%);

- the extended input voltage range allows the inverter to be used for connection to a poorly stabilized network or generator;

- compactness and low weight of the welding inverter will be useful for creating welded joints in hard-to-reach places;

- when performing work in the open air, check the protection according to the IP standard, the recommended temperature range.

Arc force, hot start and anti-sticking are standard features of modern technology. Some welding machines are equipped with a current indication, automatic open circuit voltage reduction, and other useful additions.

In any case, it is necessary to check the compliance of the equipment with the basic welding parameters. Ranges of currents for certain diameters of electrodes (thickness of workpieces) in mm:

- 35-50 A - 2 (1.5);

- 45-80 A - 2.5 (2);

- 90-130 A - 3 (3);

- 130-180 A - 4 (5);

- 140-200 A - 4 (8);

- 160-250 A - 4-5 (15).

The list shows the data for the bottom position of the rutile electrode (manual mode MMA). The actual compliance of the parameters is established taking into account the technological features of the proposed welding work.

The best inexpensive welding inverters

For a relatively rare use of technology, significant investments are economically impractical. However, a good inverter can be purchased at an affordable price. The TOP 4 models of welding machines given in this section clearly demonstrate the advantages of modern production technologies. Responsible assembly and use of high-quality components ensure reliability and long-term preservation of stable operating parameters.

1. ELITECH IS 200H (TIG, MMA)

Weighing 2.8 kg, the device does not use excessive force. The wide strap secures the inverter securely to the shoulder when moving. At maximum current, manual welding with thick electrodes (up to 5 mm) is quite acceptable. The wide input voltage range (140-250V) means that there are no significant restrictions when choosing a suitable power supply. Users note the effectiveness of the standard cooling system.At high air temperatures, the inverter remains operational even in intensive operation.

Pros:

- the best budget inverter model, taking into account the total assessment of consumer parameters;

- suitable for reproducing welding technology in inert gas atmosphere (TIG);

- lightweight compact model;

- efficient cooling.

Minuses:

- short wires;

- fan operation is not regulated (average noise level).

2. RESANTA SAI-190 (MMA)

This popular inverter model has received many positive reviews. Users note the ease of performing work steps without experience. Automation prevents "sticking", timely activates the afterburner. Flexible cables do not impede handling of electrodes in difficult conditions of access to the welded joint area. Convenient placement of adjustments simplifies setup.

Pros:

- smooth arc, good seam quality;

- reliable protection against overheating;

- built on the basis of modern IGBT transistors;

- ease of customization;

- excellent welding inverter for the garage or home;

- long working cycle (70%);

- maintaining performance in a wide range of power supply voltage (140-260V).

Minuses:

- short connecting wires.

3. Svarog REAL ARC 200 (Z238N) (MMA)

When working with 3-4 mm electrodes, a certain current reserve allows you to create an even long seam without interruption. Experts note the suitability of the inverter for professional activities. Robust steel housing prevents accidental damage. Private users note the convenience of inverter control, arc stability with a significant voltage drop in the network. The manufacturer provides an official warranty extended to 5 years for Svarog REAL ARC 200.

Pros:

- the best model of a welding machine for manual arc welding in difficult operating conditions;

- reliability;

- maintaining functionality at a minimum voltage of 160V;

- current stability;

- long-term guarantee;

- does not overheat at the maximum duration of working cycles.

Minuses:

- rigid welding cables;

- lack of a belt as standard.

4. Fubag IR 200 (MMA)

The extended range of the regulator allows you to set the welding current from 5 to 200 A with a fairly high accuracy. This feature of the Fubag IR 200 inverter is useful for optimal setting of the operating mode. The device provides the creation of an arc with a light single touch of the workpiece. Experts advise to pay attention to the evenness of the seam, comparable to the parameters of automatic analogs.

Pros:

- flawless inverter functionality at an affordable price;

- fine tuning of the current in a wide range;

- correct maintenance of arc stability;

- minimum noise level of the cooling system;

- good power reserve;

- comfortable wide belt.

Minuses:

- short duration of the working part of the cycle (40%) at maximum power.

The best welding inverters for quality and reliability

The general overview is supplemented with a special section. Here are the welding inverters that have received the highest ratings from user reviews, taking into account the reliability of the main functions. These devices are quite suitable for solving professional tasks.

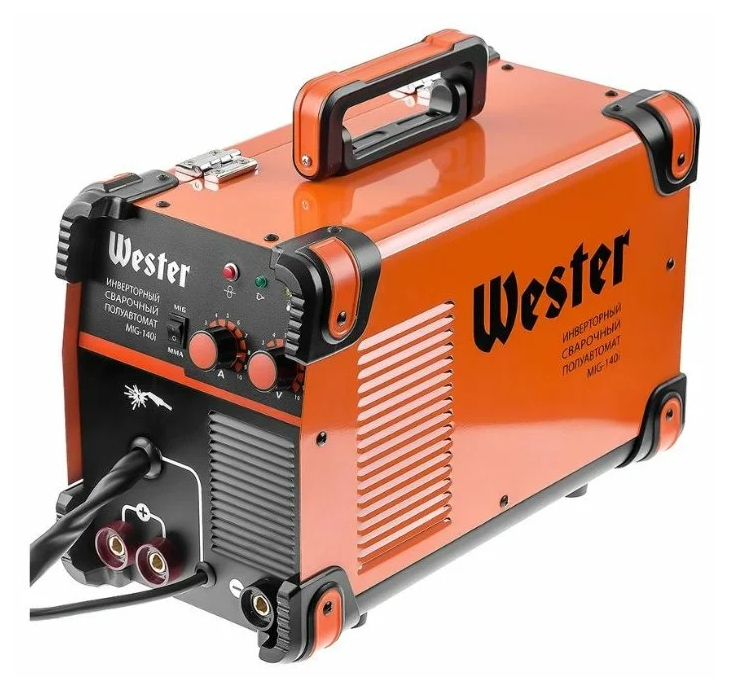

1. Wester MIG 140i (MIG / MAG, MMA)

The universal inverter is designed to reproduce manual and semi-automatic welding modes. Using argon or carbon dioxide, it is possible to create high-quality joints of workpieces from steel and aluminum alloys. With different thicknesses of metals, the seam is smooth. The built-in coil does not protrude beyond the body, which prevents accidental damage. Standard with inverter comes with wire, shield and hammer with attached brush. Electronics maintains current stability with high accuracy in the range from 40 to 140 A. The experience of operating the welding machine has confirmed the possibility of using electrodes up to 4 mm (maximum according to the accompanying documentation - 3.2 mm).

When welding parts, it is necessary to take into account the distribution of technological cycles recommended by the manufacturer: 60% - work, 40% - a break to reduce the temperature. To change the current strength and current flow rate, convenient knobs with a bright switch position scale are used. LEDs provide indication of plugging in and overheating.

Pros:

- one of the best inverters in terms of reliability, taking into account user ratings;

- automatic and manual mode (MIG / MAG and MMA);

- minimum noise level;

- well-developed cooling system;

- good power reserve (4.7 kW);

- robust steel body with protective pads on the corners;

- current stability.

2. Svarog REAL ARC 220 (Z243N) (MMA)

Choosing a manufacturer of welding machines, many buyers prefer this brand. The official warranty obligations extended to 5 years are provided by responsible assembly, careful control of suppliers and inspection of finished products. The stability of the set current is maintained by the automation at an input voltage of 160 to 270 V. Such an inverter can be connected to an independent generator. Protection prevents damage from water droplets falling vertically onto the housing. When the inverter overheats, the power supply to the working circuit is automatically cut off, the indicator light on the panel lights up.

Pros:

- long-term preservation of the original operating parameters;

- simple reliable design;

- stable arc;

- electrode diameter - up to 5 mm;

- chic functionality;

- small size;

- large power reserve;

- high-quality assembly;

- long cables;

- the ability to connect to the generator.

3. RESANTA SAIPA-200C (MIG / MAG)

This inverter perfectly copes with TIG welding in the semi-automatic mode of wire feeding into the working area. If necessary, electrodes with a diameter of up to 5 mm can be used. The stability of the output current is maintained when the supply voltage drops to 140V. The device is well adapted to perform its functions in difficult conditions. Built-in protection provides quick shutdown in case of overload. The operating parameters of RESANT SAIPA-200C are suitable for creating reliable joints of thick and thin workpieces.

Pros:

- high-quality inverter for MIG and MAG welding;

- economical gas supply using an electromagnetic valve;

- reliable wire feeder;

- stable operation of the electronic converter with good efficiency;

- simplicity and ease of customization;

- reliability and practicality in work;

- automatic prevention of electrode sticking;

- fast start.

Minuses:

- for the correct operation of the machine, beginners should study the detailed video instructions.

4. Quattro Elementi MultiPro 2100 (TIG, MIG / MAG, MMA)

This inverter can be used for manual and semi-automatic welding. Internal placement protects the spool (feed mechanism) from damage. The DC current, set by the user in the range of 10 to 190 A, is stable with a supply voltage of 185 to 240 V. The Quattro Elementi MultiPro 2100 is one of the best rated welding inverters in terms of reliability. Professionals confirm that good technical parameters are maintained even with insufficient care. Separately, it should be noted that the electrode is well fixed with a standard holder.

For the convenience of the user, the controls and controls of the inverter are grouped in one zone. A special panel groove prevents accidental mechanical damage. Electrical connectors are protected against moisture. Powerful fans keep the electronics at optimum temperature, preventing overheating during long cycle times.

Pros:

- reliability;

- two displays;

- versatility (three types of welding);

- smooth fine adjustment of the wire feed speed;

- high-quality burner and leggings as standard;

- good seam without defects;

- the ability to adjust the "afterburner" mode;

- neat assembly.

Minuses:

- an argon-arc welding torch must be purchased separately;

- solid weight (16 kg);

- limited operating range of input voltage.

The best universal welding inverters

To perform individual operations, qualified specialists use appropriate manual or automated technologies. Process optimization ensures high quality welded joints while saving consumables. The noted advantages explain the expediency of using a universal technique. Professional inverters in this category perform their functions flawlessly when operating in TIG, MIG / MAG and MMA modes.

1. Fubag IRMIG 180 SYN (TIG, MIG / MAG, MMA)

A feature of this inverter model is microprocessor control. State-of-the-art electronic software, without user intervention, optimally adjusts the operating functions for the tool used. The idle cycle voltage is automatically reduced to a safe level. Conventional or flux cored wire can be used if required. It is permissible to use a two- or four-stroke burner mode. The protective circuit monitors the load, activates a fast trip when the parameters are outside the normal range.

Pros:

- the best in the ratio price - quality inverter of the universal category;

- microprocessor control;

- smooth fine adjustment of welding current;

- burner as standard;

- compact size and light weight.

Minuses:

- maximum current - 180 A.

2. Solaris MULTIMIG-227 (MIG / MMA / TIG) (TIG, MIG / MAG, MMA)

A good state-of-the-art semi-automatic welding inverter controls individual work processes with high precision. If it is necessary to create a point connection of thin sheets, select the special SPOT mode. After the initial setting of the duty cycle time, the following actions will be performed automatically (range 0.1-10 seconds). Solaris MULTIMIG-227 accepts a large wire spool. For welding without neutral atmosphere, polarity is reversed. A special adjustment is installed in the welding machine to select the optimal arc intensity when activating the afterburner.

Pros:

- precise microprocessor control;

- stability of operating parameters in all modes (TIG, MIG / MAG and MMA);

- the ability to work at low voltage;

- high build quality and functionality at the highest level;

- wide range of welding current (from 20 to 220 A).

Minuses:

- makes a noticeable noise;

- relatively small duty cycle at high temperatures (35%, +40 degrees).

3. Aurora SPEEDWAY 180 (TIG, MIG / MAG, MMA)

You can evaluate the advantages of microprocessor control after a careful study of the operating features of the professional inverter Aurora SPEEDWAY 180. To set the optimal mode, use the standard table of settings. For example, with a workpiece thickness of 1 mm, select 17V. Further, operator corrections are not needed. Arc stability is automatically maintained until the end of the work cycle. When a short circuit occurs, the voltage drops to a safe level of 24V.

Pros:

- high-quality reproduction of professional technological operations;

- synergistic control with simple activation;

- stability of operating parameters when the input voltage drops to 160V;

- voltage reduction function to a safe level VRD;

- adjustable wire feed speed (from 3 to 11 m / min);

- digital display;

- easy to move;

- effective cooling;

- light weight and compactness.

Minuses:

- to eliminate software errors, the wire tension must be correctly adjusted.

Which welding inverter is better to buy

For the correct choice of a welding machine, it is necessary to clarify the purpose of the equipment. Consideration should be given to the thickness and material of the workpieces, the volume and duration of working operations. Consider separately:

- ease of access;

- room temperature and humidity modes;

- the need for outdoor welding.

Which welding inverter is better, you can find out after correctly defining the basic criteria.The advantages of reliable models should be emphasized. The initial investment will pay off during operation. Certain advantages are provided by the use of well-equipped equipment. Automation of individual operations prevents incorrect user actions. Our professional rating of the best welding inverters provides unbiased information to avoid mistakes when buying.

Elitech inverters are only capable of operating at normal voltage. When the voltage drops below 200V (a common phenomenon for our power grids), the welding current drops by 30-50%, which does not allow the use of electrodes thicker than 2-2.5 mm.

Resant inverters are leaders in overstating their characteristics. Placed on the 2nd place SAI-190A at a normal voltage of 230V produces a welding current not higher than 160A, with the declared 190A.